Today, with rapid technological change, efficient, precise, and intelligent production equipment and processes have become the core driving force behind industry upgrades. For many years, WH-STEEL Pipeline has consistently leveraged technological innovation to deepen its presence in the pipeline equipment field, continuously improving its workshop equipment and processes, and striving to provide customers with higher-quality products and solutions. | High-pressure, thick-walled stainless steel hot-pressed elbows successfully launched into production!

01 Leading Technology, Superior Performance

To ensure precise control of temperature, pressure, and speed during the elbow forming process, effectively improving product consistency and pass rate, each machine is meticulously controlled by eight experienced craftsmen.

Hot Pressing Process Overview:

① Heat the blank tube in a natural gas-fired furnace;

② Secure the upper and lower tires to the upper and lower worktables of the press;

③ Coat the inner cavities of the upper and lower tires with graphite powder;

④ Place the heated blank tube into the lower tire, and fill the blank tube with an inner core, spacers, and a horseshoe core;

⑤ Start the press, and the upper tire begins applying pressure to the blank tube;

⑥ Quenching: Rapid cooling changes the metal's internal structure, thereby increasing hardness, strength, or adjusting wear resistance.

Advantages of the hot-pressed pipe fitting process include:

✅ Precision Forming: Utilizing high-precision molds and an intelligent adjustment system, we ensure elbow dimensional tolerances of ≤0.1mm.

✅ Energy Saving and Environmental Protection: Optimizes energy utilization, reduces energy consumption, and meets green manufacturing standards.

✅ Durable: High-quality steel and advanced heat treatment processes extend the life of the equipment.

✅ Widely applicable: Capable of processing a variety of materials, including carbon steel, stainless steel, and alloy steel, and supporting pipe diameters from DN200 to DN600, meeting the needs of industries such as petroleum, chemical, and power generation.

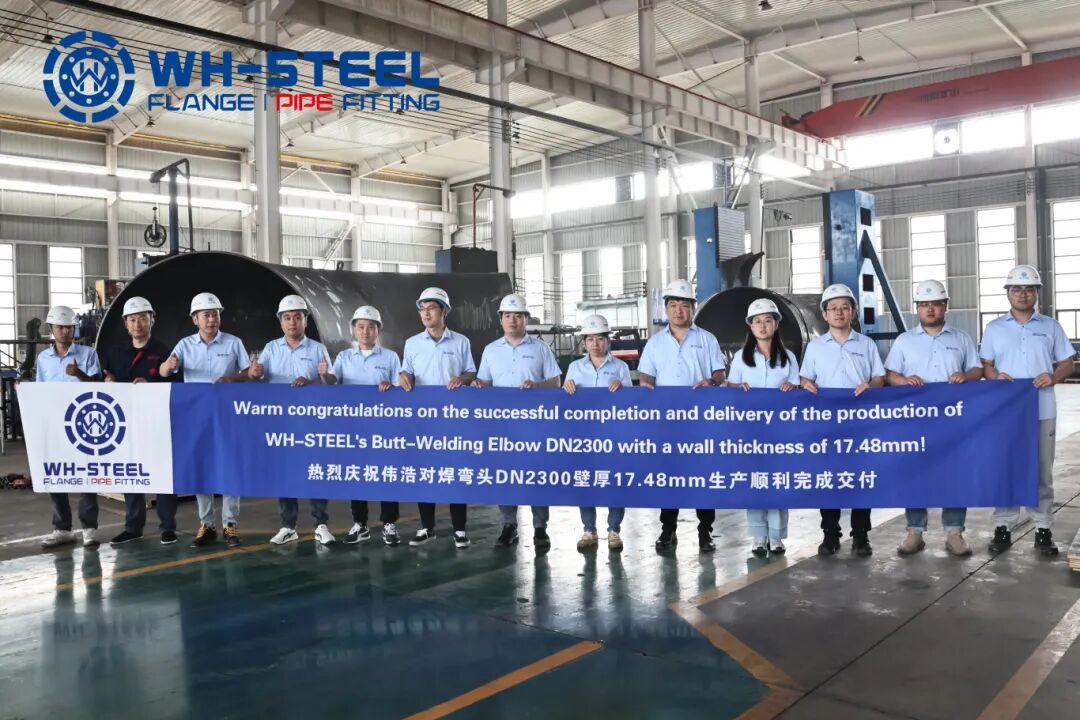

02 2.3-meter Large-Size Elbow: A Double Breakthrough in Size and Technology

This 90° long-radius elbow, DN2300, has an actual wall thickness of 21.4mm, with the wall thickness reduced to 17.48mm at the end.

Breaking Conventional Limits: The 2.3-meter diameter places extreme demands on material strength, forming accuracy, and equipment performance. WH-STEEL has significantly improved its production capabilities by utilizing the latest pipe hot-pressing technology.

High-Precision Hot-Pressing Process: Using the latest hot-pressing process, the elbow's curvature deviation is controlled within ±0.5°, and the wall thickness uniformity error is less than 1%. Both pressure-bearing performance and fluid flow rate meet industry-leading standards, perfectly meeting the demanding requirements of large-scale projects.

As a leading company in the pipeline equipment industry, WH-STEEL consistently adheres to the principle of "building reputation through expertise." From conventional pipe fittings to ultra-large-diameter customized products, every challenge serves as a testament to its technological prowess. The successful delivery of the 2.3-meter large-size elbow is not only a testament to the strength of WH-STEEL's production and technical teams, but also a strategic layout for WH-STEELo to deepen its roots in the high-end equipment manufacturing industry.

Looking Ahead: Continuous Innovation to Lead the Industry

The successful launch of WH-STEEL's high-pressure, thick-walled stainless steel hot-pressed elbows is not only a significant achievement in the company's technological innovation, but also a precise response to market demand. Going forward,WH-STEEL will continue to increase R&D investment, promote intelligent manufacturing upgrades, and help global customers achieve efficient and high-quality pipe processing and production