In June 2025, WH-STEEL was awarded the Laboratory Accreditation Certificate (Registration Number: CNAS L23523) issued by the China National Accreditation Service for Conformity Assessment (CNAS), namely the CNAS Accreditation! This marks another important milestone in WH-STEEL’s development journey, signifying that the management system and technical capabilities of the Testing Center of WH-STEEL Pipeline Technology Co., Ltd. have met the strict requirements of ISO/IEC 17025:2017 General Requirements for the Competence of Testing and Calibration Laboratories (CNAS-CL01). As China’s only official laboratory accreditation body, after obtaining CNAS accreditation, the company is entitled to use the CNAS mark and the ILAC (International Laboratory Accreditation Cooperation) mutual recognition mark. For WH-STEEL, CNAS accreditation is not only a "technical pass" but also a "competitive moat," which indicates a significant improvement in WH-STEEL’s core competitiveness in products.

Authorized by the Certification and Accreditation Administration of the People's Republic of China (CNCA), the China National Accreditation Service for Conformity Assessment (CNAS) is a signatory to the mutual recognition arrangements of the International Laboratory Accreditation Cooperation (ILAC) and the Asia Pacific Accreditation Cooperation (APAC). It is responsible for implementing the national accreditation system for conformity assessment.

CNAS’s authoritative accreditation is a high recognition of WH-STEEL’s comprehensive strength. Its review system is professional and rigorous. Obtaining CNAS accreditation means that the testing center has established a standardized, scientific, and traceable system in all aspects, including personnel qualifications, equipment calibration, environmental conditions, testing methods, quality control, and result reporting. This ensures the authority and international mutual recognition of testing, and further reduces WH-STEEL’s compliance costs. At the same time, the improvement of technical capabilities and international recognition also signifies the high technical assurance and high added value of WH-STEEL’s products.

The successful acquisition of CNAS accreditation this time is the result of WH-STEEL’s unremitting efforts in adhering to technological innovation, strictly controlling product quality, and pursuing excellence over the long term. For many years, WH-STEEL has kept in mind its business philosophy: "Build a reputation with professionalism and provide customers with reliable, hassle-free, and reassuring comprehensive services and products." WH-STEEL clearly recognizes that the quality and safety of pipeline products are the cornerstone of engineering construction. Establishing a high-level in-house testing center and obtaining national authoritative accreditation demonstrates WH-STEEL’s attitude of striving for perfection in product quality and its determination to consolidate core competitiveness.

Looking ahead, WH-STEEL will continue to enhance its comprehensive service capabilities, strictly abide by high standards and strict requirements, and take CNAS accreditation as a starting point. It will continuously strengthen its technical capabilities, optimize service standards, provide customers with more high-quality, efficient, and valuable pipeline products and solutions, and strive to become the most trusted comprehensive service provider of pipe fittings and pipelines for customers.

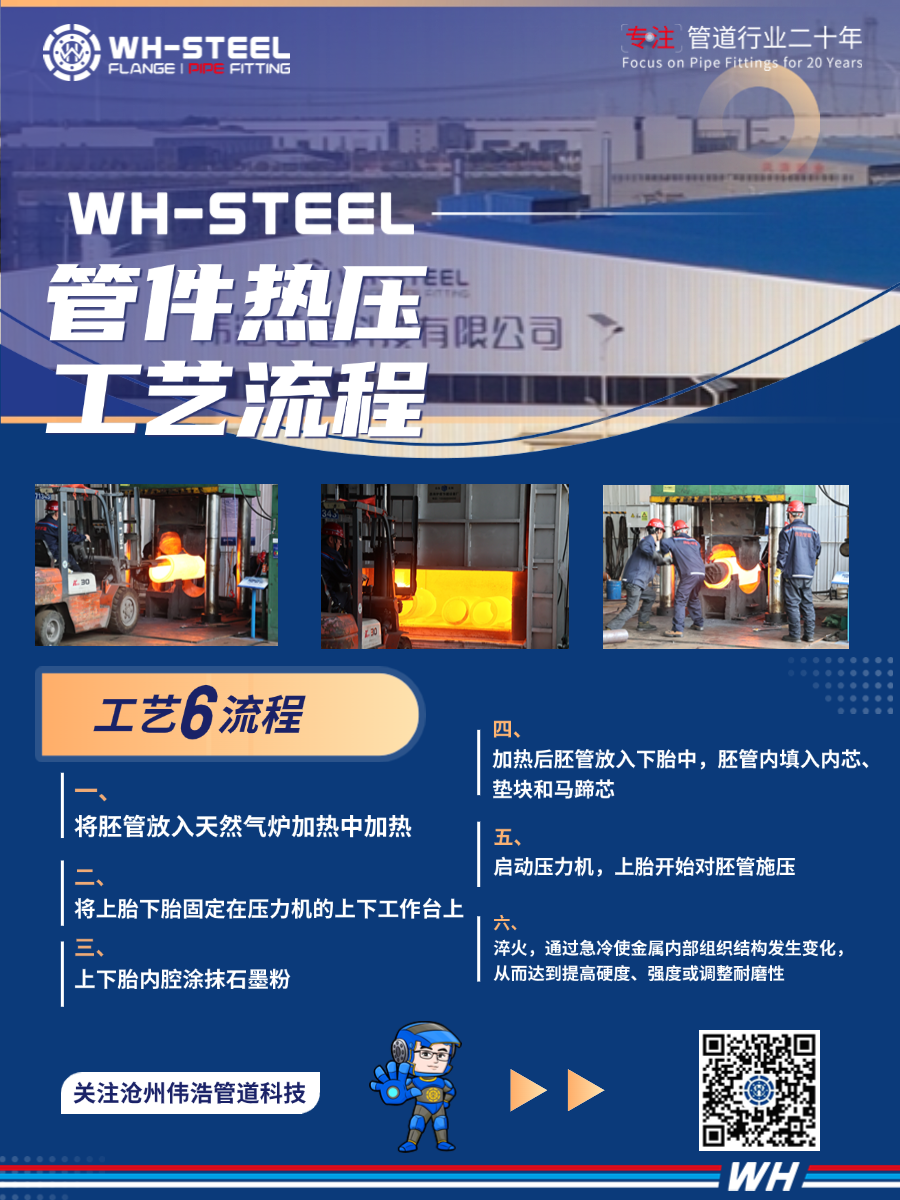

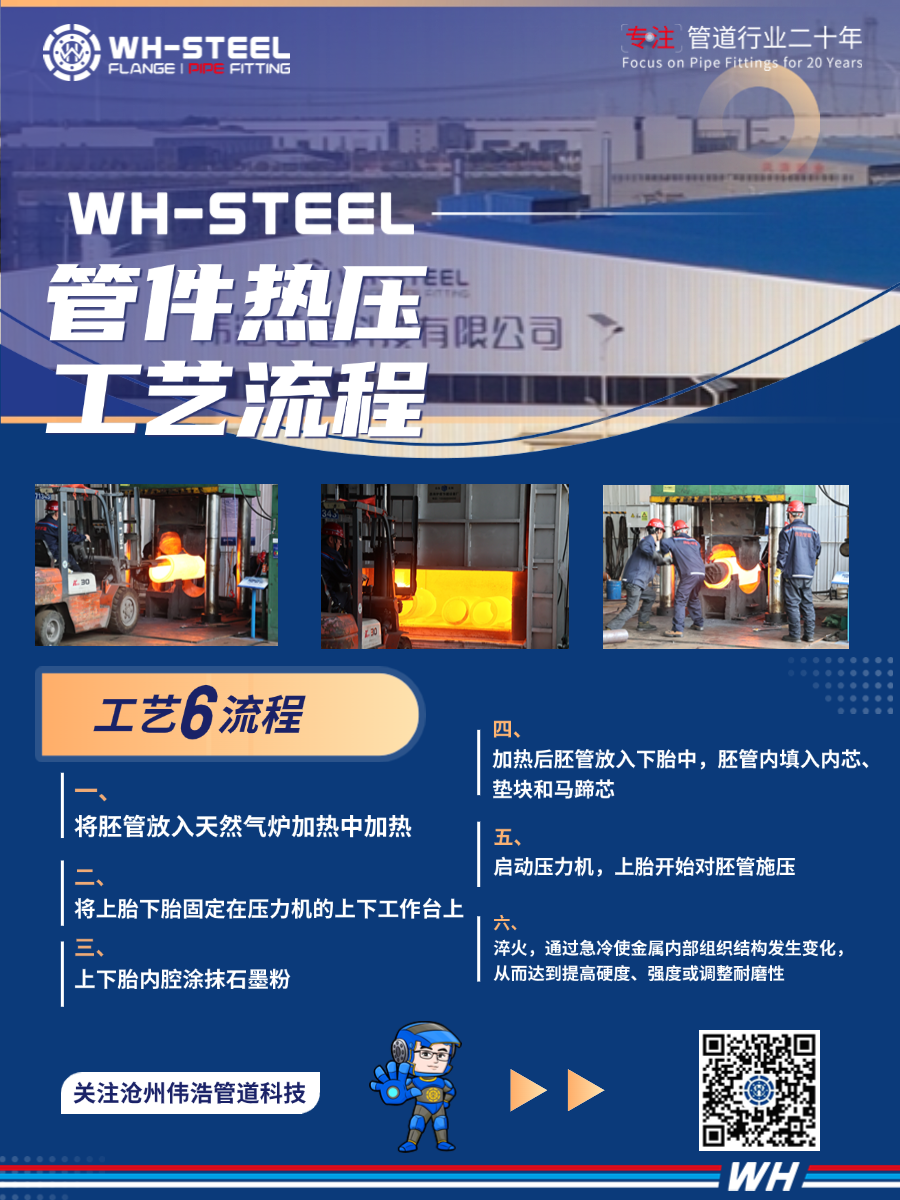

[Recent Major Event Poster]

Recently, Weihao’s high-pressure thick-walled stainless steel hot-pressed elbows have been successfully put into production! They boast multiple advantages as follows:

Ø Precise Forming: High-precision molds and an intelligent adjustment system are adopted to ensure the dimensional error of elbows is ≤ 0.1mm.

Ø Energy Conservation & Environmental Protection: Energy utilization is optimized to reduce energy consumption, complying with green manufacturing standards.

Ø Strong Durability: High-quality steel and advanced heat treatment technology extend the service life of the equipment.

Ø Wide Applicability: Capable of processing various materials such as carbon steel, stainless steel, and alloy steel; supports multiple pipe diameters ranging from DN200 to DN600, meeting the needs of industries including petroleum, chemical engineering, and electric power.